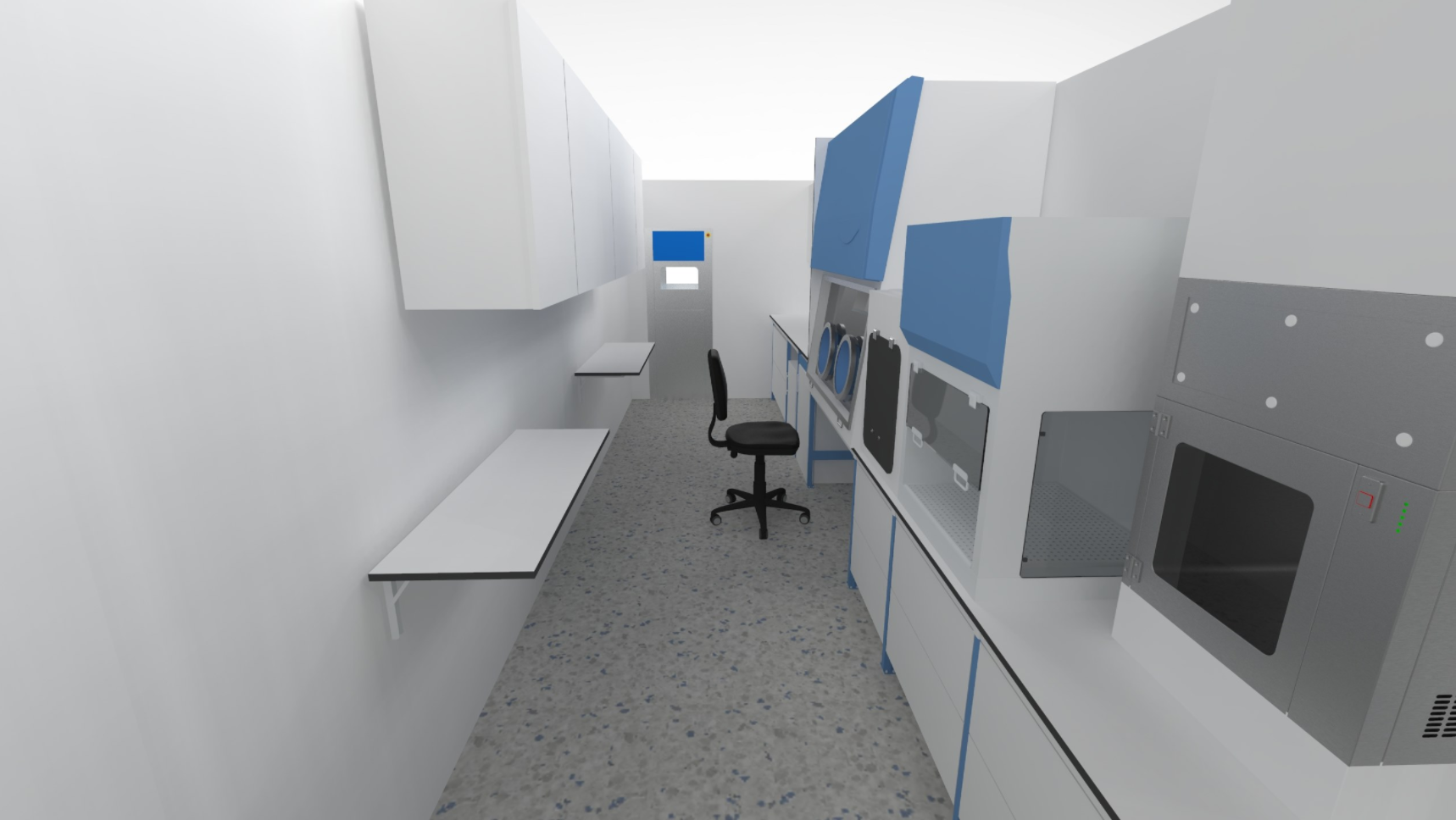

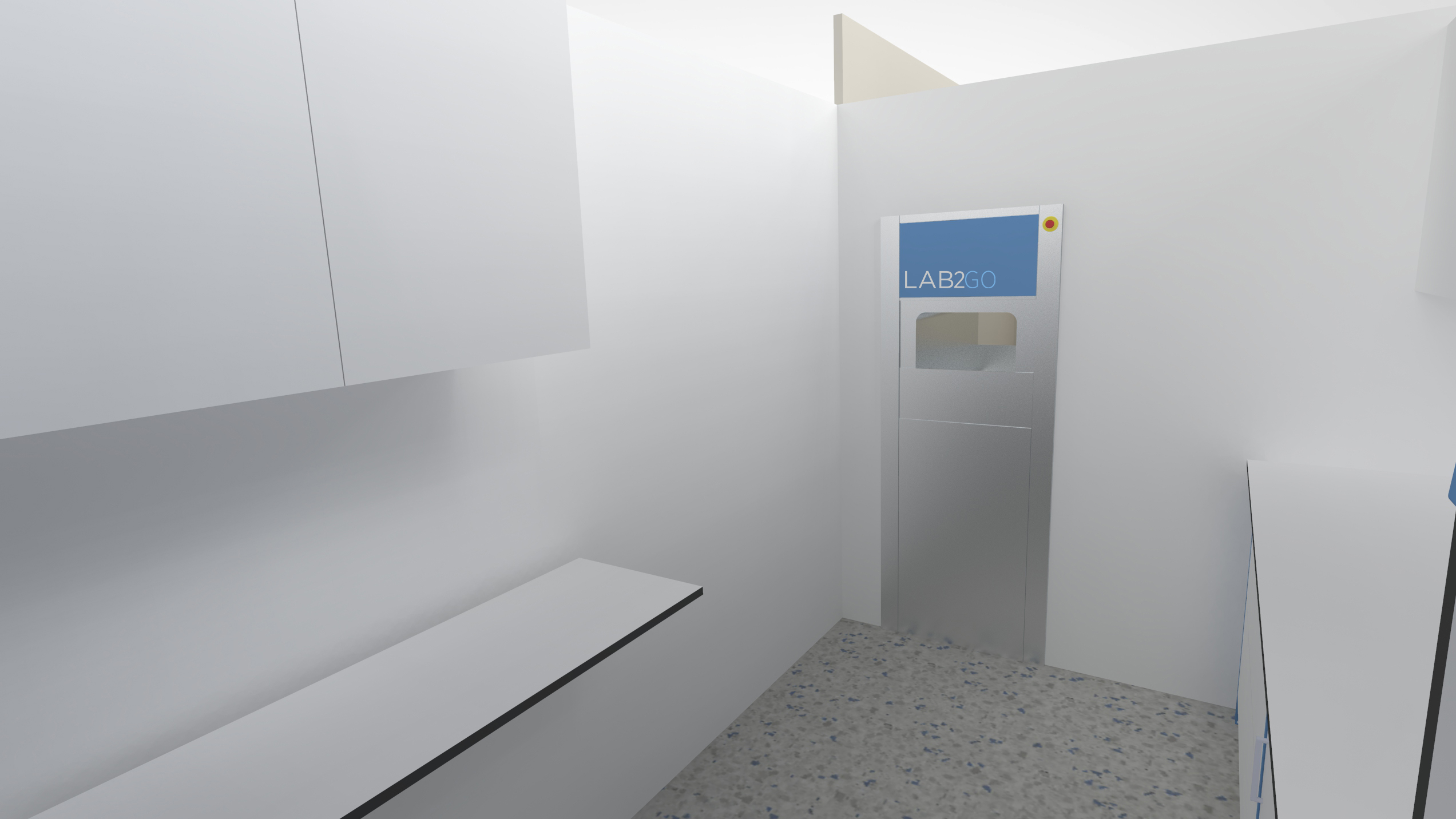

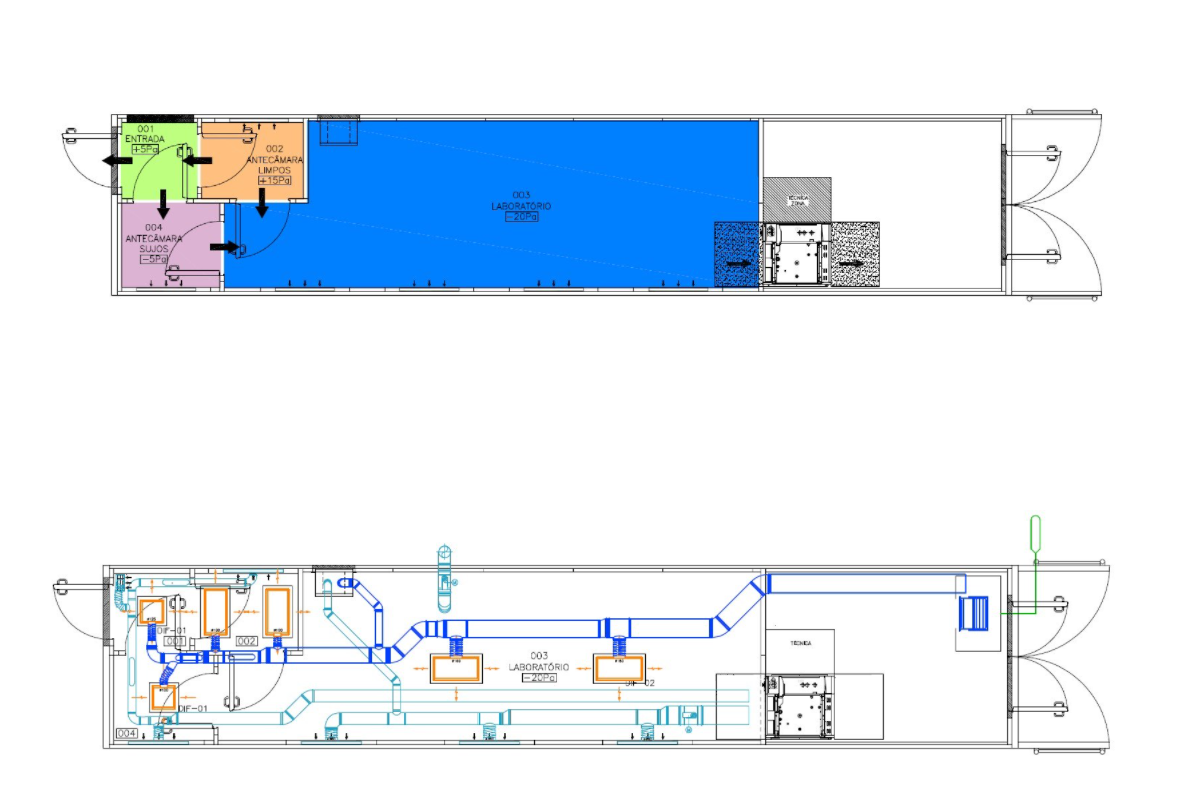

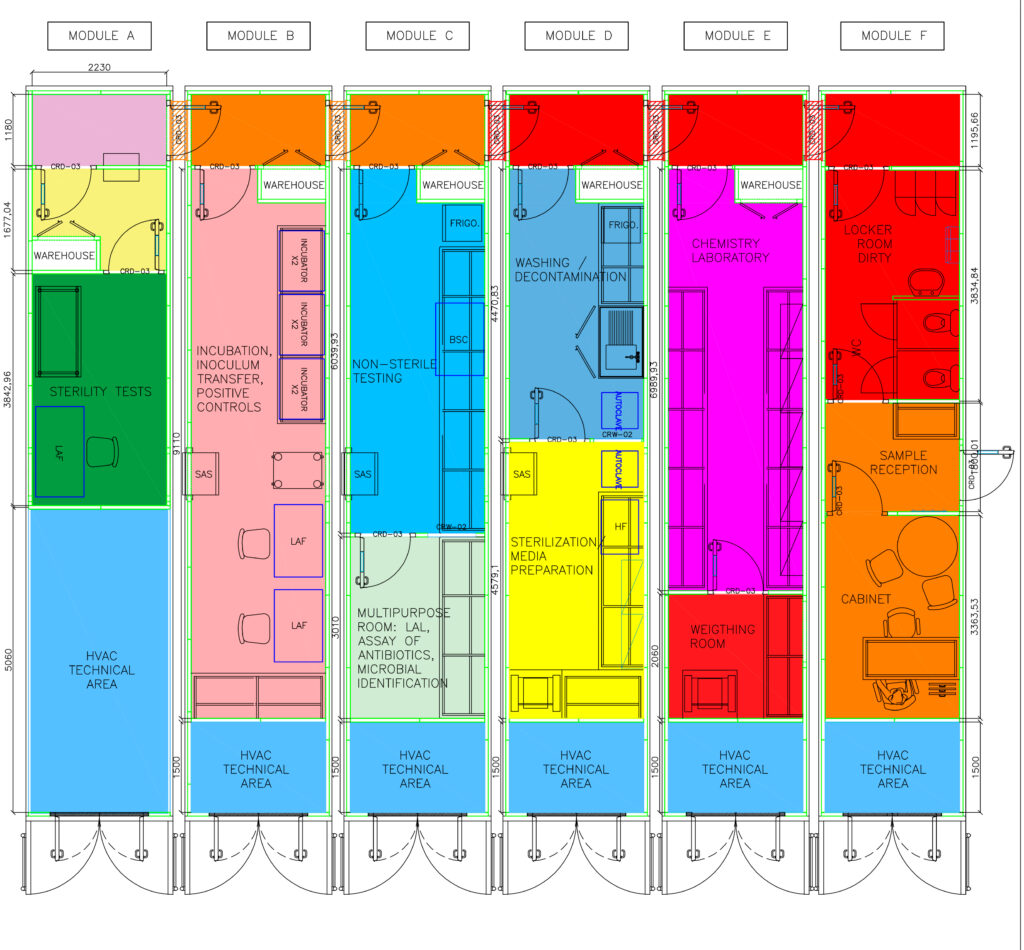

Modular or maritime containers (20′, 40′ or 40′ high cube) are used to house technology equipment and as healthcare temporary workstations. These containers offer high durability, are waterproof, capable to handle extreme outdoor conditions and are a cost effective solution. They are easily movable and can be shipped by air, sea or land.

Standard sizes and others sizes available on demand